-

تواصل معنا

-

أرسل لنا بريدًا إلكترونيًا

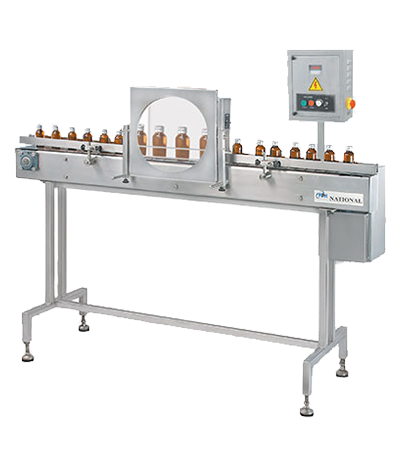

Visual Inspection (Magnifying Dome)

OVERVIEW

NPM's visual inspection machine for filled bottle is made of high quality stainless steel and is equipped with a magnifying dome. It consists of a durable stainless steel chain 3½" in the center that moves and brings in the bottles from the capping machine conveyor in front of the magnifying dome for inspection. Here, the operator can efficiently inspect the bottles, thus it requires no manual intervention while inspection. Through the magnifying dome, the operator checks for any partials in the liquid contents filled, faults in sealing and physical integrity of the bottle and if any inconsistencies are found, they manually reject the bottle. Post inspection, the bottles are sent for further operation. The machine is manufactured with superior quality stainless steel with support for adjusting the height of the table top mechanism.

SPECIFICATION

| Technical Specifications | ||

|---|---|---|

| Model | NVBID - 100 | NVBID - 150 |

| Output / Hour* | 2400 to 3600 bottles | 3600 to 4800 bottles |

| Number of operator | One (1 x 1, One side seated) | Two (1 x 2, Two side seated) |

| Dome Diameter | 360 mm (1 No.) | 360 mm (2 Nos.) |

| Direction of Movement | Left to Right | |

| Power Characteristics** | 0.5 HP / 220 V / 50 Hz | |

| Height of Conveyor** | 860 ± 50 mm | |

| Input Specifications | ||

|---|---|---|

| Container Size** | Round Shape | Diameter: ∅ 22 mm to ∅ 60 mm*** |

| Respective Height : 58 mm to 120 mm | ||

| Flat / Square | Length : 30 mm to 70 mm | |

| Width: 20 mm to 50 mm | ||

| Height: 58 mm to 120 mm | ||

| * Depends on bottle size, cap size and type of cap. | ||

| ** Can be customized. | ||

SALIENT FEATURES

- Structure is made of SS 304 30 mm sq. Pipe, 16 SWG with matt finish.

- A/C frequency variable drive.

- Direct gear drive.

- Bigger size magnified Acrylic dome for Pre-Inspection.

- Adjustable height of conveyor belt, to align with other machine of the line

- Self-alignment bearing for easy maintenance.

- Rigid Vibration free Construction for trouble free performance.

For more details, Please click here.